Materials | Free Full-Text | Natural Aging of Ethylene-Propylene-Diene Rubber under Actual Operation Conditions of Electrical Submersible Pump Cables | HTML

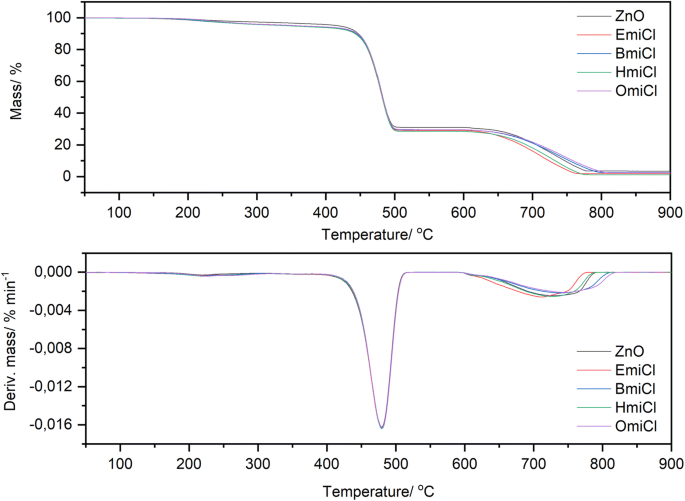

Thermal analysis applied to studying the influence of ionic liquids on the vulcanization, thermal stability and damping properties of ethylene- propylene-diene rubber | SpringerLink

Thermo-reversible crosslinked natural rubber: A Diels-Alder route for reuse and self-healing properties in elastomers - ScienceDirect

Thermoreversible cross-linking of ethylene/propylene copolymer rubbers - Polymer Chemistry (RSC Publishing)

Ethylene Propylene Rubber Market - Global Industry Perspective, Comprehensive Analysis and Forecast, 2020 - 2026

Influence of epoxidized ethylene propylene diene rubber on nonisothermal crystallization kinetics and mechanical properties of poly(butylene terephthalate)/polypropylene blend

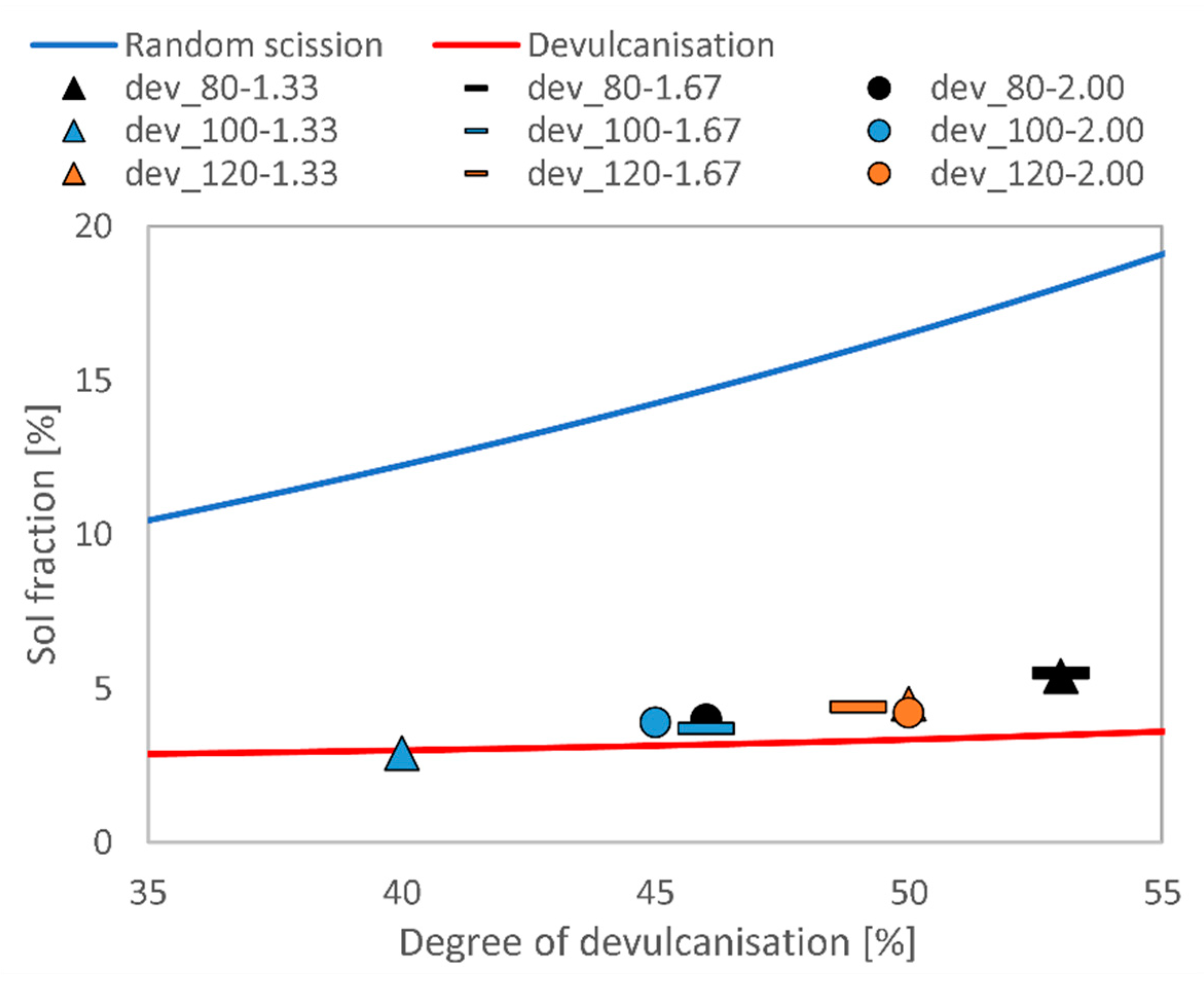

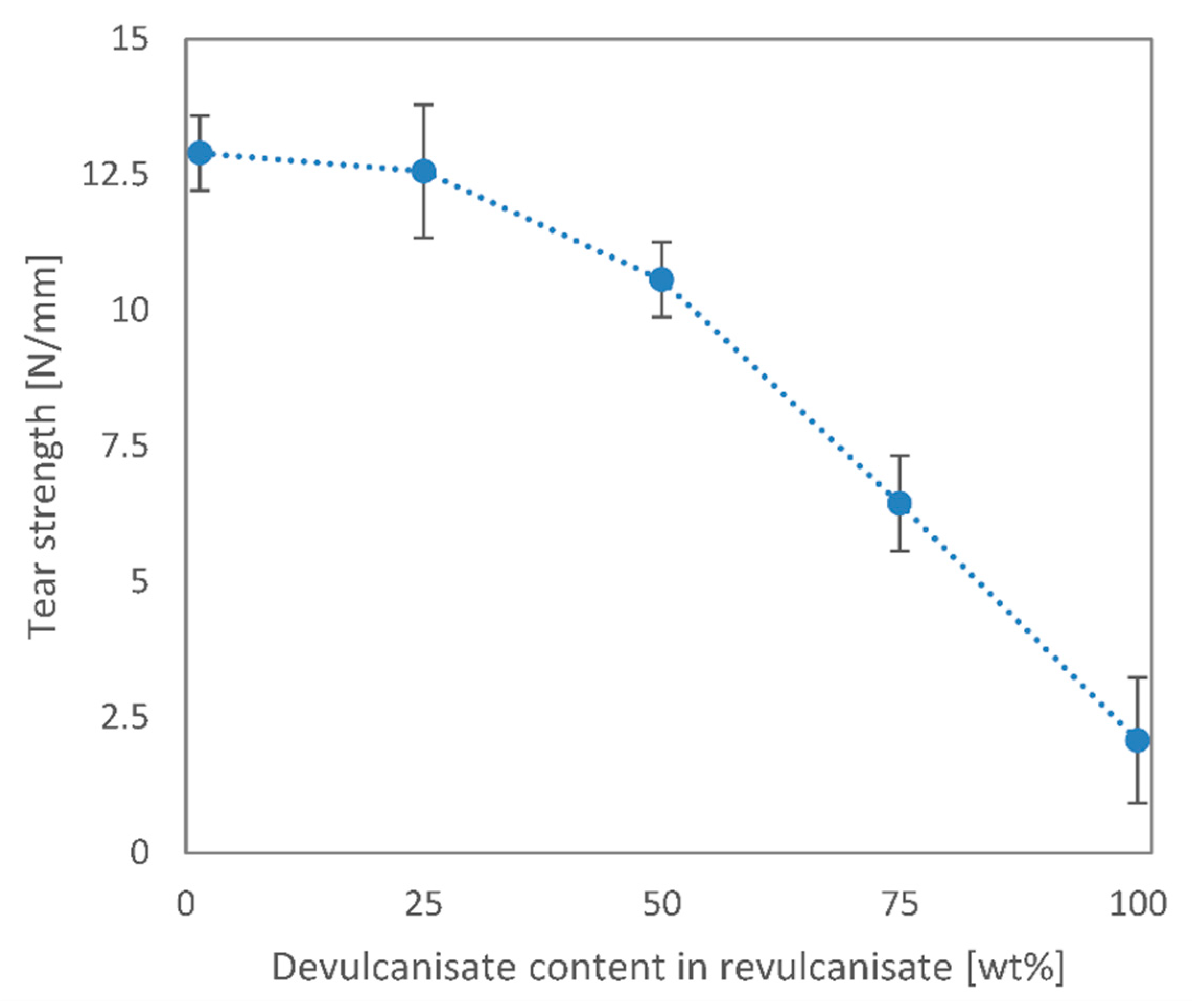

Polymers | Free Full-Text | Thermomechanical Devulcanisation of Ethylene Propylene Diene Monomer (EPDM) Rubber and Its Subsequent Reintegration into Virgin Rubber

Particle size distribution of ethylene-propylene diene monomer rubber... | Download Scientific Diagram

Polymers | Free Full-Text | Thermomechanical Devulcanisation of Ethylene Propylene Diene Monomer (EPDM) Rubber and Its Subsequent Reintegration into Virgin Rubber | HTML

Effects of virgin Ethylene–Propylene–Diene–Monomer and its preheating time on the properties of natural rubber/recycled Ethylene–Propylene– Diene–Monomer blends - ScienceDirect

Polymers | Free Full-Text | Thermomechanical Devulcanisation of Ethylene Propylene Diene Monomer (EPDM) Rubber and Its Subsequent Reintegration into Virgin Rubber | HTML

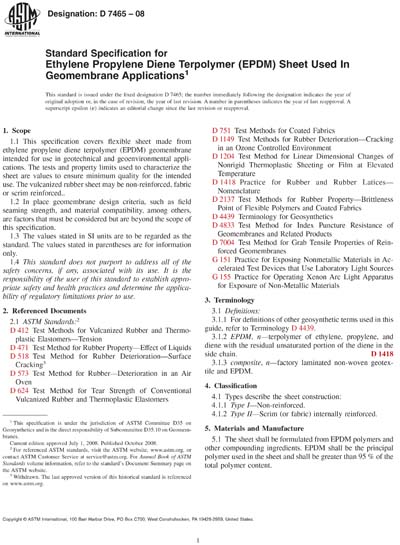

ASTM D7465-08 - Standard Specification for Ethylene Propylene Diene Terpolymer (EPDM) Sheet Used In Geomembrane Applications

Thermo-responsive shape memory polymer blends based on alpha olefin and ethylene propylene diene rubber - ScienceDirect

Enhancing the thermal stability of natural rubber/recycled ethylene– propylene–diene rubber blends by means of introducing pre-vulcanised ethylene–propylene–diene rubber and electron beam irradiation - ScienceDirect

Poly(propylene)/waste vulcanized ethylene- propylene-diene monomer (PP/WEPDM) blends prepared by high-shear thermo-kinetic mixer | Semantic Scholar

Poly(propylene)/waste vulcanized ethylene- propylene-diene monomer (PP/WEPDM) blends prepared by high-shear thermo-kinetic mixer | Semantic Scholar